How Bottled Water is Made

So have you ever just taken a minute to think about the amazing process that goes behind getting bottled water to you? So let us deep dive into the world of water packing bottle machine! This smart device is used for filling bottles with pure and refreshing drinking water. We'll take a closer look at this incredible machine next.

Advantages

The water packing bottle machine has been a modern day innovation that completely changed the essence of how bottling happens for pure drinking waters. Several benefits in comparison to traditional ways For starters, it is very quick and reliable. You have the ability to fill hundreds of bottles in just moments... cutting labor time and increasing your level of production. Not only this, but also identification of cleanliness with no chance a contamination With this automated water filling system, it reduces the touch of human skin and decreases germ transmission. At the end, this is an economical option. Made of A Grade materials so that you can avoid the repairing and maintenance with high pricing, in long-term this saves your money.

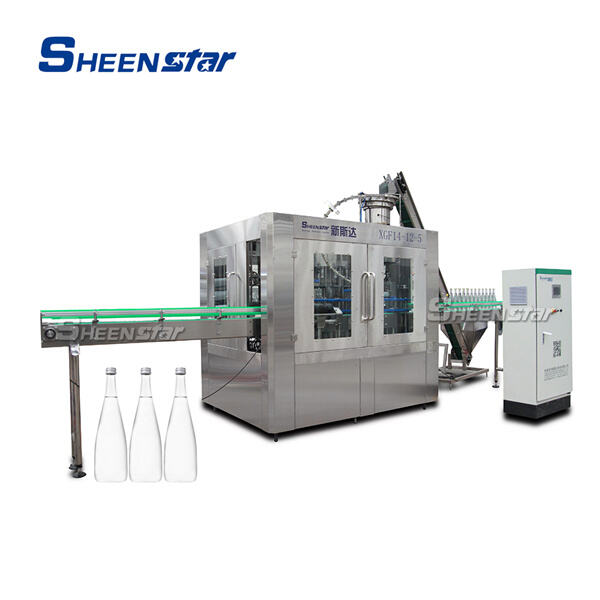

What precisely separates the water packing bottle machine from standing out is truly finding development lying at its heart. User-oriented, all facilities are devised to enable consistent accuracy and output speed. Using sensors the machine is able to detect and fill up each bottle with correct required quantity of water, hence no room for under or overfilling. Their conveyor system moves bottles from one end to the other with ease, saving a good amount of time and effort. GIMPACT has a slim and compact design which saves floor space in the production line area further increasing overall efficiency.

Food safety is important, and also food and beverage production can be in top water packing bottle machine. The machine automates the process to cut-down human intervention and unintended spillage of water which can be dangerous in a workplace. The machine maintains strict vigil through its sensors and any irregularities are nipped in the bud, systematically shutting down all systems of operation keeping operator informed to prevent accidents. Also, the apparatus is carefully constructed from food-grade materials to supply drinkable water.

How to Use

The water packing bottle machine is operated without any hassles. All the operator has to do is fill a reservoir with demineralized water, and the machine does everything else. Bottles are fed onto the conveyor, and filling is accomplished by machine with minimum human interaction. It has sensors to know how big each bottle is and fills it with the exact amount of water. At the end of line, a cap will then be placed onto it which effectively "seals" and makes the bottle ready for distribution. The role of the operator is to observe and see that machines are functioning alright.

Machines require service and the water packing bottle machine is backed by a specialized support division that provides ongoing help as well. Issues or defects are resolved almost immediately, with the team also performing regular check-ups on the machine to ensure it always runs at its peak performance. They also do training sessions to operators so that they are adapt with the running of machinery, which leads to minimal accidents and malfunctions.

The high quality standards for drinking water production are strictly enforced by the machine and that is perfectly fine. And it does that, with water being certified uncontaminated during the filling process and materials utilized for its production are all food-safe. With this level of detail all done in the name of quality, consumers can never go wrong when it comes to providing pure and fresh drinking water.

Sheenstar 15 Years rich experience in the industry of beverage machinery has integrated production, R and D, after-sales services and sales Accredited through ISO9001, CE, SGS and many other certifications. Our team can design the best machine for each client in accordance with market research, inquiries, budget. The customers of Sheenstar extremely pleased with the services and equipment provided by our company. We have a Water packing bottle machinename in the world of water and beverage machines.

From raw material procurement through production manufacturing, we have a skilled knowledgeable Water packing bottle machineinspection team. Our quality inspection department on the lookout for every detail to ensure that all equipment meets high standards of quality requirements. The matials are high quality SUS304/SUS316. They are easy clean and has long life expectancy as well as the electrical components of a known brands with good quality and good after sales service.

Sheenstar offers complete Water packing bottle machineproduction systems, including pure water, fruit drinks, wine, soymilk, oil, yogurt. Containers made plastic, glass barrels of 5 gallon cans. The entire line comprises water treatment system, beverage pre-treatment system, injection molding machine and bottle-making machine, refilling filling machine, labeling system, packing machine, other machinery.

Customization options available to meet the requirements of our customers. We can supply layout diagram for the factory along with the bottle's label. We will also provide Water packing bottle machine of production during the production process of the machine. Additionally, we have a professional after-sales service department can provide quick and thorough technical support. The engineers will visit the customer factory install and test the machines' operation and train the workers in the proper use of and maintenance of machines, ensuring the normal operation of the equipment as well as the smooth process customer production.

Water Packing Bottle Machine is widely used in water bottling plants, supermarket chains and hotels. It is a constant source of providing consumers with clean and pure drinking water. With its affordability and ease of use, this testing is helpful even for the producers at a moderately small scale. With the increase in demand for bottled water, one item that is fast making its presence felt as a necessary addition to this lucrative industry are machines like the water packing bottle machine and it looks set for more expansion.