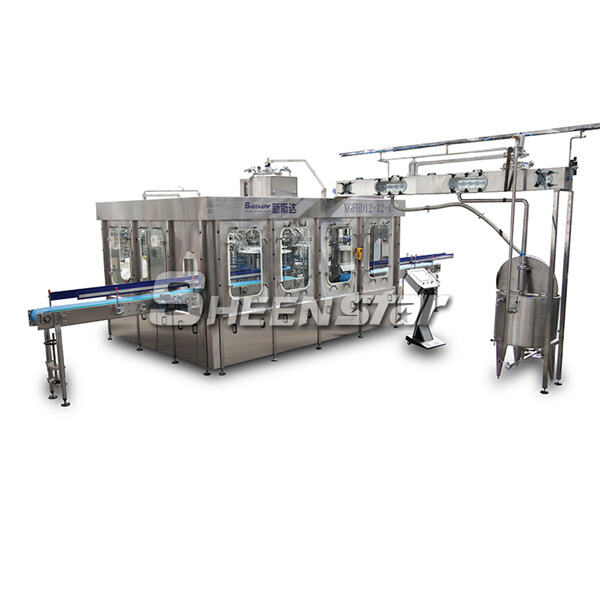

An Automated Bottle Filling Machine Turnkey For Businesses

Auto bottle filling machine has brought a whole new paradigm in the operation of businesses, just like the Sheenstar's product called rinser filler capper machine. This new breed of the device has also revolutionized and simplified different procedures in other sectors, including features that help businesses stand out on market competition. In this article, we are going to explain the great features of AI technology that come with its business benefits and why you may include it in your company.

Speed and Efficiency:

A huge benefit of the auto bottle filling machine is its impressive speed. This machine is much faster in comparison with manual methods, the operator can fill hundreds of bottles for per minute. This increased efficiency can translate into substantially improved productivity and smooth business expansion in the market at a faster pace.

Precision and Accuracy:

In order to be able to fill bottles its a machine matter of precision and this is precisely what the equipment that we are covering in this post excels at. Unlike the manual filling process, which can be inconsistent and error-prone; an auto bottle filling machine will guarantee that each and every unit is filled as required to the max. This level of accuracy reduces material waste, ensures product consistency and improves productivity.

Customer satisfaction is key to consistency;

Customer satisfaction is rarely consistent and the auto bottle filling machine solves that as well. This machine fills all bottle sizes with consistent quality and quantity, beats manual operations and helps in building brand loyalty. Product quality at a consistent level not only provides companies with differentiation from competitors but also relationships that will be durable over time.

Features That Come with Advanced Upgrade

Its new-age sensors have made it the latest auto bottle filling machine version. These sensors expertise to monitor bottles at filling station with assurance of automatic, accurate and non-spill dispensing the product across automated method. This contemporary Filling Machine is more efficient than the conventional methods.

User-Friendly Interface:

An automated bottle filling machine, alongside its user-friendly touch screen console makes it simple to run. It allows operators to watch real-time progress of the machine and control in a more seamless way using an interface. This user-friendly feature reduces human errors, increases fill efficiency and simplifies of operations.

High level of energy efficiency and ecosustainability

Energy efficiency is critical for businesses, particularly in this age requiring sustainability, also the water packing machine supplied by Sheenstar. As we all know plastics waste dropped every day and this issue has very critical for mother nature now a effective auto bottle filling machine resolve this problem by giving high output with quite low input getting not only economical however environmental friendly. Businesses can opt for this machine to improve their sustainability factor and lower the operational expenses.

Safety Measures:

Safety remains the key objective for all industries and why an auto bottle filling machine has automatic cut-off which shows that it takes operator safety seriously. The safety run stops the machine if there happen to be any break failures or other unintended hold-up, a feature that will prevent injuries. On top of this, an Alert System alerts operators in case a component is broken to keep your work environment secure.

Operator Protection Security Guards:

In addition to the above factors, an auto bottle filling machine means equipped safety guards which protects operators from probable hazards while operating. They serve as a security shield to prevent any harm between the operator and moving parts of machine, avoiding accidents leading towards safe working environment.

How to Use:

Liquid renderer settings for liquid type and fill volume are available, with appropriate values to be selected based on the specific case of each operator These are parameters that help the machine to interpret how it can work best and issue an appropriate amount of glue, similar to the Sheenstar's product like liquid filling machine.

Filling Process:

Once the machine is installed, bottle loaders can easily fill bottles by loading them in its self-contained chamber. Correct bottle positioning is crucial in order for a trouble-free application of the patch.

Initiating Filling Sequence:

So, operators would press the fill button on the machine to start pushing product. At the moment of this action, an automation sequence is launched with very high speed and accuracy.

During filling operation, operators will observe through the touch screen interface, along with the bottle packing machine built by Sheenstar. It detects and corrects any deviations or defects very quickly to make sure that the filling results are repeatable and of high quality.

Regular Cleaning Routine:

The auto bottle filling machine requires regular cleaning in order to maintain its efficiency and the quality of product. Regular cleaning ensures the integrity of the machine and its maximum service life, avoiding residues to be stored in it is important that production always remains hygienic.

Lubricates the chain for best overall performance.

Lubricating machine parts at regular intervals to reduce friction, prevent wear and tear, and extend operational life, same with Sheenstar's juice bottle filling machine. Machine oiling ensures that machines manage downtime well and run smoothly.

Routine Inspections:

As with any machinery, the auto bottle filling machine needs to be maintained frequently so that it performs optimally. Additionally, veritably qualified inspections on schedule are capable of pinpointing any potential issues and ensuring that a well-maintained piece of equipment remains in optimal performance condition with minimal downtimes.

Focus on Quality:

The auto bottle filling machine has become a valuable commodity as it is highly dependable and ensures that the standards of quality are met. Being able to choose from a good manufacturer will ensure that businesses get the best machinery and on top of it, they should also fulfill their requirements.

Sheenstar offers complete Auto bottle filling machineproduction systems, including pure water, fruit drinks, wine, soymilk, oil, yogurt. Containers made plastic, glass barrels of 5 gallon cans. The entire line comprises water treatment system, beverage pre-treatment system, injection molding machine and bottle-making machine, refilling filling machine, labeling system, packing machine, other machinery.

From raw material procurement through manufacturing production Our company has a knowledgeable experienced quality inspector team. The quality department our company continuously monitors every stage to ensure sure that the equipment used is up to high quality standards. The equipment is of premium quality SUS304/ SUS316, which easy to clean and have longevity of service and Auto bottle filling machinecomponents made by a well-known brands that have excellent quality and a good after sales service.

Sheenstar 15 Years rich experience in the industry of beverage machinery has integrated production, R and D, after-sales services and sales Accredited through ISO9001, CE, SGS and many other certifications. Our team can design the best machine for each client in accordance with market research, inquiries, budget. The customers of Sheenstar extremely pleased with the services and equipment provided by our company. We have a Auto bottle filling machinename in the world of water and beverage machines.

We provide personalized customization services allows us to customize filling machine solutions based on the Auto bottle filling machine needs of customers. We will provide a factory layout diagram as well as the bottle's design and label. We can also provide a production schedule during the production process of the machine. Additionally, we have a professional team of technicians can provide timely and thoughtful support. The engineers will visit manufacturing facility the customer to install, test and run the equipment. They also will train workers on how to operate and maintain the equipment. This ensures the smooth operation of the equipment, and progress of the production.

Auto Bottle Filling Machine

A bottle filler fits in with industries that need high volume and efficient liquid product filling, also the juice bottle filling machine innovated by Sheenstar. This machine provides an economical solution and higher production capacity whether in the food and beverage industry or the pharmaceutical industries. The auto bottle filling machine helps lower the operation cost apart from quantifying packaging, but also has an affect on improvement of the bottled drink quality and improves market competitiveness.