Happy New Year! 2026 comes with fresh hope and possibilities. At this moment of transition, we extend our warmest wishes to you—our valued client and partner. Thank you for the trust you placed in us over the past year. Every project, every col...

Read More

Welcome new and collaborated customers to visit the SHEENSTAR factory recently. The workshop is currently debugging and operating a blowing filling capping combi. The equipment has a production capacity of 24000bph, and one machine can comp...

Read More

If you are about to start a new water production factory, Sheenstar's machines are your perfect choice.The newly shipped water filling machine from sheenstar, with a production capacity of 24,000 bottles per hour, employs electronic valve technology ...

Read More

SHEENSTAR workshop has just shipped a fruit juice filling machine. The filling section of this machine employs weight-based filling. A weight-based filling machine is a high-precision liquid filling device, whose core working principle involves real-...

Read More

This carbonated beverage production line was completed earlier and recently underwent trial operation in the workshop. The filling and packing line runs fastly and smoothly, with a filling speed of up to 12,000 bottles per hour. The entire production...

Read More

Recently, the SHEENSTAR Workshop manufactured a six-in-one machine capable of filling loose tea. Tea is transported to the filling device via a feeding tray, and the process stops when the weight on the circular electronic scale reaches a preset valu...

Read More

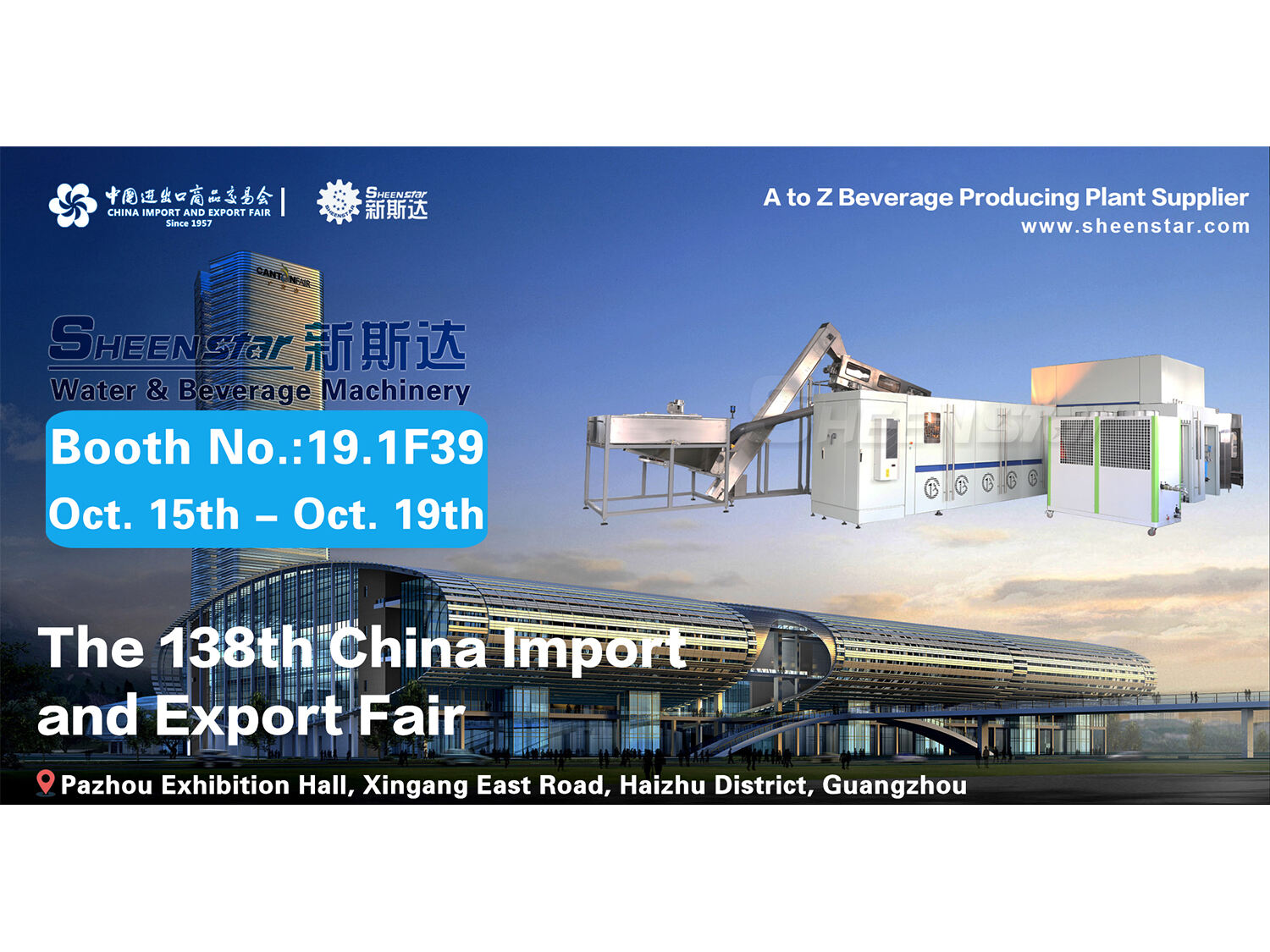

Sheenstar will attend the 138th Canton Fair, from Oct. 15th to Oct. 19th Welcome to our Booth: 19.1F 39, Area D Our colleagues will meet you at the booth and introduce you to our company's new equipment and services. If you are planning to start a ne...

Read More

A new 24 head filling machine has been put into production at the customer's factory, which uses top brand components such as Siemens, Danfoss, and Schneider, with excellent performance. Through CE certification, it ensures compliance with EU safety ...

Read More

During the peak season of beverage production, sheenstar is busy sending its filling production line to customer factories. This time we shipped a small production filling line with a capacity of 5000 bottles per hour. This water production line is u...

Read More

In a water filling production line, a blow molding machine is used to produce plastic bottles, and the power consumption of the blow molding machine accounts for the majority. There is a high-temperature oven inside, which needs to evenly heat the pr...

Read More

This 12-12-4 large bottle water filling machine has been installed and debugged in sheentar workshop. This machine can not only fill 5 liter plastic bottles, but also 10 liter plastic bottles, as long as some parts are replaced. We will go to the cus...

Read More

Recently visits to Sheenstar Factory revealed multiple machines undergoing trial operations, including this newly commissioned 4-in-1 glass bottle filler. Designed for pemelo juice packaging in 1000ml glass bottles, it achieves a production rate of 3...

Read More Hot News

Hot News2025-12-31

2025-12-02

2025-11-14

2025-10-31

2025-10-24

2025-10-17