Wonderful Soft Drink Production Line — Technology Leading To a Great Taste and Safe SodasA smattering of soda lover here? Messaging Are you an Oasis, For Locomotion (a cool drink in hot summer days)? I mean take a look at the soda line. Now, producing this ravishing technological gem of a device that offers all the types of soft drinks to be consumer-friendly anywhere as whenever they want.- On top for our product conclusion line showing vast success in bulk production since everyone can drink according their quality with design & safety without new discoveries about debauchery- Desires serve millions popular Now focusing on four primary advantages benefit from just one series specific item performing well special because these are possess individual utility friends enjoying prestige across nations out there; giving how brilliantly utilizes Soft Drink Production Line allows generations uses excellently high standards performance why proud using what actually.

Today, we will yield a attending at some above differences amid acceptable assembly and activity through the Soft Drink Production Line. For one thing, it is able to make many soft drinks quickly so as to meet the customers demand in time. This line is designed for high-yield, efficient and automated production. Secondly, each batch yields sodas with sweet count-to-count accuracy (with the assist ingredient). Quality & Taste Reliability... Third, run fewer employees throughout the entire production line than any other traditional soft drink factory = savings in time and manpower. Plus, it is built to last and require little upkeep for less downtime.

Soda processing is a major shift on the production line, boasting numerous technological advances. The most advanced of these features are in-line carbonation, in-line blending and batching systems. Inline carbonation, where the CO2 is introduced to a pipe of water for even distribution. In soda bottling plants, in-line blending allows the concentrate to be mixed with water so that it would pass a known specific gravity and flowrate (for fizz), while ensuring you have exactly properties and flavour practice based measurements from consumer standards. In contrast with bulk processing systems that are used to transfer the slugs of material for mixing multiple separately conveyed ingredients and a finished good batching system - notionally an object unto itself - refers to how much from each ingredient precisely in which order is dispensed into where when during what phase of every batch making it.

It should be noted that safety of workers is an important factor in the configuration for soft drink on line production. It is equipped with a control system which will automatically take care of the entire manufacturing process requiring minimal work from humans. This removed the chance of infection, evertthing will be performed in a closed system. Moreover, for coronary health are used food-grade materials of the highest quality on a high-quality production line. It makes the cleaning and sterilization process simple thus reducing chances of contamination by using unwanted microbes during meal preparation.

Soft drink production line is relatively simple and easy to set up. The first thing to do is get the water supply line and production hooked up so that there will be enough pressure for your wash process at temperature. They would be added to your carbon dioxide supply so that you can have fizzy soft drinks. Choose the concentrate you want and in what quantities... after that a factory is doing all succor. The soft drink is then quality and flavour taste tested, before packaging.

Sheenstar 15 Years rich experience beverage machinery industry that integrates production, R and D, after-sales services sales certified through ISO9001, CE, SGS and various other certifications. Our team can design the ideal machine for each client according to research, requests, and budget. Sheenstar's customers extremely satisfied with the services equipment provided by our company. We have a prestigious Soft drink production linein the field of water and beverage machines.

From procurement Soft drink production linematerials all the way to manufacturing and production, we a skilled and experienced quality inspector team. quality inspection department strictly controls every step to ensure that each piece of equipment is in compliance with the highest quality standards. Materials SUS304/SUS316 of excellent quality, simple clean, and with long-lasting life. Electrical components are famous brands, which have excellent quality, good service and after-sales support.

We offer customization Soft drink production lineto meet the needs of our clients. can design bottle labels, label and also provide a outline of the factory layout for customers. We also provide an estimated production schedule for the process. Additionally, we have a team of skilled technicians who can offer timely and attentive support. Engineers will visit the client's factory install, test and run the equipment. They will also educate workers how they can make use of and maintain the machines. This will ensure the smooth operation of the equipment and the speed of production.

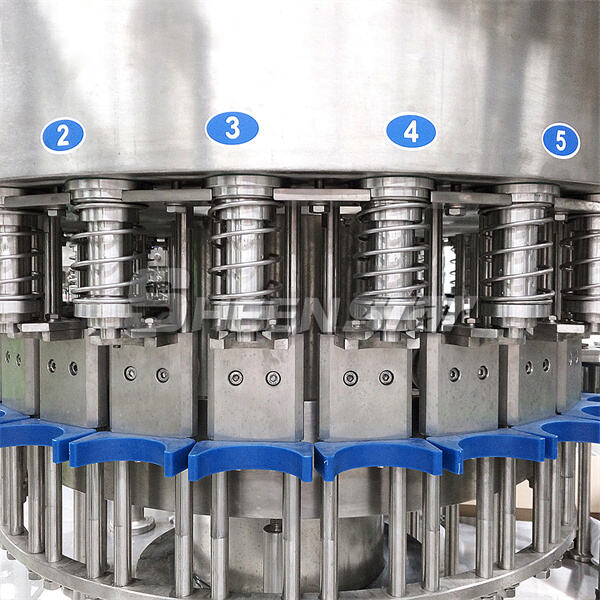

Sheenstar offers complete range of beverage manufacturing solutions, such pure water, juice from fruits carbonated drinks, oil, wine, soy milk yogurt and more. Contianers may made of glass bottles, plastic containers, 5 gallon barrels cans. The entire line includes water treatment system, beverage pre-treatment system, injection molding machine bottle making machines, refilling filling machine labeling system, packing Soft drink production line, and various other auxiliary machines.

A soft drink production line is available in many industries worldwide. Large commercial beverage producers use these lines to mass-produce soft drinks for retail markets. Machine Manufacturing Company Made Use in Production Lines Beverage processing - Soft drink production lines, Juice proccessing Line Water Bottling and Beer Brewing : The company may sell machines for soft drinks product,line or dedicate their machines to juice, water bottle and beer brewing. Those small-to-mid-level food service or catering companies serving soft drinks will also benefit from the convenience of using these production lines to make their own soda in house.

Aerated Drink Quality and Services Offered

Soft Drinks: produced with good quality in soft drink production line In other words, the production line ensures that mixing is homogeneous and you have a consistent taste of correct catch for every measure. Also since it is automated the control system, contamination can be nearly eliminate keeping a very high safety and quality standards. It gives its customers installation, maintenance services and training on a special basis that no other soft drink production line suppliers offer. You receive top-notch customer service, technical assistance and those products are also guaranteed on default.