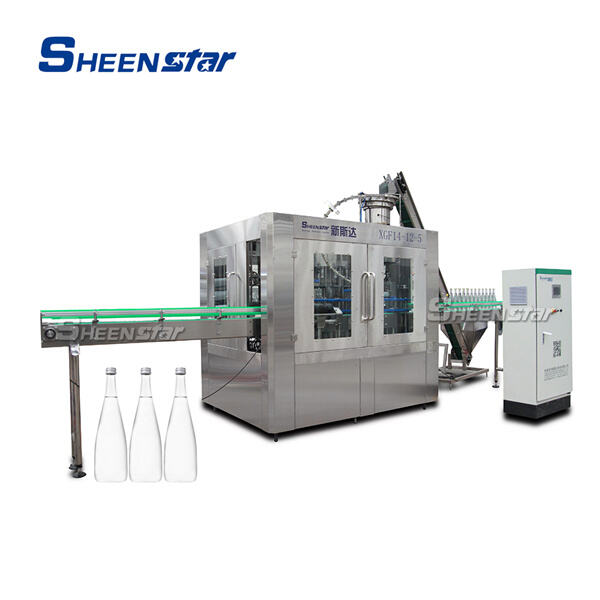

What is Bottling Equipment? Bottling equipment is a machine that fills and seals liquids into containers. This machine is essential for commercial manufacturing and industries that sell meals, drinks, and beauty items. The Sheenstar bottling equipment is responsible for filling the item, sealing the container, labeling, and packaging it in a safe manner. The equipment will come in different sizes and shapes to suit products in various industries.

Bottling equipment has several manufacturing advantages in the industry. First, it helps increase productivity by filling containers quickly and accurately. This can help reduce labor costs and produce high volumes of products. Secondly, this Sheenstar water bottling equipment is uncomplicated to use, and it also needs minimal maintenance. It saves time, energy, and resources, allowing the industry to create products efficiently. Thirdly, bottling equipment is reliable, durable, and safe to be used. It meets all the standards that can be international regulations the production industry.

Bottling equipment has went through long periods of processing, innovation and new technology. The modern equipment is sold with advanced features such as automatic capping and filling, heat control, and item line automation. These features make sure the manufacturing industry produces high-quality products. Additionally, the Sheenstar automatic bottling machine is now more environmentally friendly, leaving a reduced carbon footprint.

Bottling equipment is safe to work with when operated correctly. The machine comes with safety features such as sensors, shields, and protective measures counter accidents. It is crucial to stick to the manufacturer's recommendations regarding the usage and maintenance of this machine. This helps to make sure the safety of the users even though the customers associated with the products.

Using the bottling equipment is also extremely easy. First, you require the most to make sure the grade for the product and prepare the containers. Then, you have to check the Sheenstar bottling line equipment to make sure it is connected and working properly. Next, you'll want to start the stuffing monitor and process it closely. Finally, you need to seal the containers and label these products.

5. Service and Quality of Bottling Equipment

The grade of bottled products largely varies according to the quality and reliability of the bottling equipment. Therefore, to assure the quality best results when using the machine, it is crucial to purchase or lease from a professional and dependable manufacturer. These manufacturers offer after-sale services, including installation, training, and technical help. Also, the Sheenstar water bottling equipment for sale is sold with a warranty, and you can contact the manufacturer’s customer service for further assistance for those who have any pressing problems with the equipment.

Sheenstar offers complete beverage production solutions, including pure water, fruit juice, carbonated drinks,oil, wine, soy milk yogurt and others. Contianers could be plastic bottles, glass bottles,5 gallon barrels or cans. The entire line includes a water treatment system and beverage pre-treatment systems, well as Bottling equipmentmolding machine bottle making, rinsing, filling, capping, packing machine.

Sheenstar is a 15-year old business vast experience in the field of Bottling equipmentmachinery. We provide production, R and D sales, sales, and after-sales services, and are accredited ISO9001, CE and SGS certifications. We will configure suitable machines for our customers based on the market research, inquiry, and budget. Customers highly satisfied with the equipment and services. Sheenstar has outstanding reputation in the water and beverage machinery sector.

Customization services offered to satisfy the Bottling equipment of our clients. We can supply an industrial layout diagram, design bottle and label. When the machine is in production, we will provide production schedule. Also, we have skilled after-sales service department that can provide timely and thoughtful technical support. The engineers will visit customer factory to install and test the equipment. They also will train workers on to operate and maintain the machines. This ensures the smooth operation of the equipment, and the efficiency of the production.

From procurement raw material to production and manufacturing Our company a knowledgeable and knowledgeable quality Bottling equipmentteam. The quality inspection department on the lookout for every detail to ensure that every equipment is in compliance with the highest high-quality requirements. The materials SUS304/SUS316 of superior quality, easy to clean and has a long life span. Electrical components world famous brands, which have excellent quality, good service and after-sales support.