This producing line is for making bottle preforms and caps

1. Pet Preform Injection Molding Machine For Small Bottles

Parameter of machine

| DESCRIPTION | 单位 | PET800-V6/S6 | PET850-V6/S6 | PET1200-V6/S6 | PET1205-V6/S6 | PET1500-V6/S6 |

| International size rating | UNIT | 1600-736 | 2000-950 | 2000-1088 | 2880-1088 | 2880-1440 |

| INJECTION UNIT | ||||||

| Screw diameter | mm | 52 | 52 | 60 | 60 | 67 |

| Shot volume | cm | 520 | 520 | 763 | 763 | 1040 |

| Shot weight(@PS1.05) | g | 473 | 473 | 693 | 693 | 945 |

| Shot weight(@PET1.3) | g | 605 | 605 | 888 | 888 | 1210 |

| Shot weight(@PP0.9) | g | 379 | 379 | 556 | 556 | 757 |

| Screw stroke | mm | 245 | 245 | 270 | 270 | 295 |

| CLAMPING UNIT | ||||||

| Clamping force | KN | 1600 | 2000 | 2000 | 2880 | 2880 |

| Opening stroke | mm | 440 | 490 | 490 | 550 | 550 |

| Max.daylight | mm | 940 | 1040 | 1040 | 1160 | 1160 |

| Space between bars(HxV) | mm | 460x460 | 510x510 | 510x510 | 610x610 | 610x610 |

| Movable platen size(HxV) | mm | 705x705 | 775x755 | 775x755 | 850x850 | 850x850 |

| Max.mold height | mm | 500 | 550 | 550 | 610 | 610 |

| Min.mold height | mm | 160 | 230 | 230 | 280 | 280 |

| Ejector stroke | mm | 145 | 160 | 160 | 175 | 175 |

| Ejector force | KN | 77 | 99 | 99 | 111 | 111 |

| Ejector force | KN | 55 | 77 | 77 | 77 | 77 |

| Number of ejecto pins | PCS | 4+1 | 6+1 | 6+1 | 12+1 | 12+1 |

| POWER UNIT | ||||||

| Hydraulic system pressure | MPa | 17.5 | 16 | 16 | 17.5 | 17.5 |

| Pump motor power | KW | 18.5/21.8 | 18.5/21.8 | 22/42 | 22/42 | 30/51 |

| Heater power | KW | 14.66 | 14.66 | 17.92 | 17.92 | 23.5 |

| Total current | A | 104/108 | 104/108 | 117.5/150 | 117.5/150 | 147.5/171 |

| GENERAL | ||||||

| Oil tank capacity | L | 280 | 420 | 420 | 560 | 560 |

| Machine weight | T | 4.9 | 6.4 | 6.5 | 8.8 | 8.8 |

| Machine dimensions(LxWxH) | m | 5.3x1.3x1.8 | 6.0x1.4x2.1 | 6.0x1.4x2.1 | 6.5x1.53x2.2 | 6.5x1.53x2.2 |

Main components in the machine

| NO. | NAME | SPE/MODEL | ORIGINA OF BRAND |

| 1 | Charging motor | INTERMOT | Italy |

| 2 | Proportional valve | YUKEN | Japan |

| 3 | Direction valve | YUKEN | Japan |

| 4 | relief valve | YUKEN | Japan |

| 5 | Computer (full set) | TECHMATION | Taiwan |

| 6 | Oil pump | ECKERLE / SUMITOMO | Germany/Japan |

| 7 | Mold adjusting hydraulic motor | EATON/WHITE | USA |

| 8 | Electronic meter | GEFRAN | Italy |

| 9 | Thermocouple | RONGDA | China |

| 10 | Air switch | MERLIN GERIN | France |

| 11 | Travel switch | SCHNEIDER | France |

| 12 | Photoelectric switch | SUONENEG | China |

| 13 | Proximity switch | SUONENEG | China |

| 14 | Thermal relay | SCHNEIDER | France |

| 15 | Thermal relay base | SCHNEIDER | France |

| 16 | Single pole automatic switch | SCHNEIDER | France |

| 17 | Double pole automatic switch | SCHNEIDER | France |

| 18 | AC contractor | SCHNEIDER | France |

| 19 | Precision oil seal / dust seal | NOK | Japan |

| 20 | Ductile iron castings | ZHONGTIAN (QT500-7) | China |

| 21 | Tie bar | GENERAL&GENESIS /HUDINH | China |

| 22 | Screw and barrel | HUAYE/taistar | China |

| 23 | Servo Motor | Phase/SNMA | China |

| 24 | Drive part | MODROL/Inovance | China |

Free spare parts for reference only

| 1 | Injection nozzle | 1 | ||

| 2 | Long injection nozzle | 1 | ||

| 3 | Material distributor | Nozzle head | 1 | |

| 4 | Collar | 1 | ||

| 5 | Gasket | 1 | ||

| 6 | Heater | 3-4 | Nozzle/barrel | |

| 7 | Thermocouple | 1 | ||

| 8 | AC Contactor | 3 | ||

| 9 | O Ring | NOK/Japan | 1 set | |

| 10 | Oil Seal | NOK/Japan | 1set | |

| 11 | Dust Seal | NOK/Japan | 1set | |

| 12 | Pressure Meter | 1 | ||

| 13 | Shock Proof Pad | 6-8 | ||

| 14 | Mold clamp | 6-8 | ||

| 15 | Toolbox 13'' | 1 | ||

| 16 | proximity switch | 1 | Mold adjustment | |

| 17 | Limit Switch | 1 | safe guard | |

| 18 | Thermal Relay | 1 | Over-loading protection |

2.Auto loader with two hopper XC-XY900G2

| Model | XC-XY900G2 | XC-XY900G3 | XC-XY900G4 | ||

| Motor(Hp/kw) | 1.5/1.1 | 2/1.5 | 3/2.2 | ||

| Conveying Capacity(Kg/h) | 440 | 500 | 590 | ||

| Loading Distance(m) | 4 | 4 | 5 | ||

| Static Wind Pressure(mm/H,o) | 2400 | 2400 | 2400 | ||

| Storage tank Volume(L) | 7.5x2 | 7.5x3 | 12x4 | ||

| Conveying Tube Inner Diameter(mm) | Φ38 | Φ38 | Φ38 | ||

| Specification Of The Attached Hoses(mm) | Φ38mmx5m 4Pcs | Φ38mmx5m 6Pcs | Φ38mmx5m 4PcsΦ51mmx5m 4Pcs | ||

| Dimension(cm) | 50x55x109 | ||||

| Approx.Net Weight(Kg) | 68 | 82 | 113 | ||

3.Dryer 600kg XCD-900U

| Model | XCD-80U | XCD-120U | XCD-160U | XCD-230U | XCD-300U | XCD-450U | XCD-600U | XCD-750U | XCD-900U |

| Heater Power(Kw) | 4 | 4.5 | 6 | 9 | 12 | 15 | 18 | 18 | 18 |

| Blower(Kw) | 0.135 | 0.21 | 0.215 | 0.32 | 0.32 | 0.32 | 0.5 | 1.5 | 1.5 |

| Hopper Capacity(L) | 80 | 120 | 160 | 230 | 300 | 450 | 600 | 750 | 900 |

| Dimensions HxWxD(mm) | 933x730x500 | 1175x730x505 | 1195x810x610 | 1495x865x610 | 1490x980x730 | 1840x1005x725 | 1815x1215x920 | 1975x1255x920 | 2085x1345x1010 |

| Floor Stand HxWxD(mm) | 864x732x550 | 865x735x550 | 865x800x670 | 865x800x670 | 1015x950x790 | 1015x950x790 | 1145x1200x1000 | 1145x1200x1000 | 1040x1270x1220 |

| Whole Height(mm) | 1510 | 1750 | 1725 | 2010 | 2080 | 2430 | 2425 | 2575 | 2600 |

| Air Outlet Pipe Diameter | 2" | 2.5" | 2.5" | 3" | 3" | 3" | 4" | 4" | 4" |

| Suction Box Pipe Diameter(mm) | Φ38 | Φ51 | |||||||

| Approx.Net Weight(Kg) | 80 | 90 | 110 | 110 | 110 | 130 | 200 | 220 | 250 |

4.Chiller 30HP air type

Main technical configuration

| No. | Main technical configuration and parameters | YDL-30F |

| 1 | compressor | Panasonic (Japan) |

| 2 | evaporator | Shell and tube type (stainless steel shell and tube, stainless steel heat exchange tube) |

| 3 | expansion valve | Alco (United States) |

| 4 | filter | Alco (United States) |

| 5 | solenoid valve | Alco (United States) |

| 6 | Water pump | CNP (China) |

| 7 | Pressure controller | FENSHENG(China) |

| 8 | water pressure gauge | CK (Taiwan of China) |

| 9 | High and low pressure gauges | SK (Taiwan of China) |

| 10 | Fan | Weima (Shanghai) |

| 11 | AC contactor | schneider |

| 12 | thermal relay | schneider |

| 13 | temperature control | Microcomputer LCD digital display (dual display of actual temperature and set temperature) |

| 14 | structure | Box type integral type |

| 15 | Surface Treatment | Powder coating |

| 16 | Water tank form | Stainless steel insulation type |

| 17 | Temperature Control Range | 7~35℃ |

| 18 | refrigerant | R410 |

| 19 | Protector | Compressor overload protection/high and low pressure protection/water cut-off, water shortage protection/phase sequence protection/water pump overload/fan overload protection |

Performance parameters of YDL-30F air-cooled box type industrial chiller unit

| Unit model | YDL—30F | |||

| Cooling capacity | 81kw | |||

| 69700Kcal/hr | ||||

| Use power supply | 3N-380V±10%:50Hz±2% | |||

| Whole machine input power | Kw | 29 | ||

| compressor | type | Fully enclosed vortex type | ||

| Qty | sets | 2 | ||

| Input power | Kw | 23 | ||

| chilled water | Inlet water temperature | ℃ | 12 | |

| Outlet temperature | ℃ | 7 | ||

| Flow | m3/h | 14 | ||

| Pipeline specifications | mm | DN65 | ||

| condenser | Type | Efficient copper tube and aluminum foil tightly expanded finned heat exchanger | ||

| fan | Input power | Kw | 3 | |

| electric current | A | 9 | ||

| chilled water pump | Type | Vertical pipeline water pump | ||

| Input power | Kw | 4 | ||

| flow | m3/h | 30 | ||

| External lift | Mh2O | 28 | ||

| External dimensions | length | mm | 2760 | |

| width | mm | 1100 | ||

| height | mm | 1900 | ||

| Nominal capacity of water tank | L | 400 | ||

| Unit weight | kg | 950 | ||

5.Compression molding machine components

Configuration

| MACHINE | ITEM | NAME | Brand Origin | |

| Plastic cap molding machine (Hydraulic) | Hydraulic system | Oil pump | PARKER HANNIFIN | USA |

| Oil cylinder | CUSTOMIZED | CHINA | ||

| Oil valve | BEIBUJINGJI | TAIWAN | ||

| Hydraulic rotary valve | YUKEN | JAPAN | ||

| Hydraulic station Motors | WANNAN | CHINA | ||

| Extruder motor | WANNAN | CHINA | ||

| Compression molding motor | WANNAN | CHINA | ||

| Electric system | Transducer for Mold plate | ABB | SWISS | |

| Transducer for Extruder | ABB | SWISS | ||

| PLC | SIEMENS | GERMANY国 | ||

| Touch screen | FANSY | CHINA | ||

| Solid state Relay | OMRON | JAPAN | ||

| Auxiliary relay | OMRON | JAPAN | ||

| Temperature module | HUIBANG | CHINA | ||

| Breaker | SCHNEIDER | FRANCE | ||

| Thermal relay | SCHNEIDER | FRANCE | ||

| Contactor | SCHNEIDER | FRANCE | ||

| Direct current switch power supply | MEAN WELL | TAIWAN | ||

| Reduction box | GUOMAO | CHINA | ||

| Cooling system | High pressure chiller for oil fffpumpopumppump | 5HP | CHINA | |

| High pressure chiller for mold | 5HP | CHINA | ||

| Mold system | Mold (core & cavity) | S136HH | SWEDEN | |

| Mold Plate | Nodular Cast Iron | CHINA | ||

| Others | Material Feeder | SHINI | TAIWAN | |

Compression molding machine Specification

| TYPE | 16C |

| Cap diameter | 18mm-60mm |

| Cap height: | 12mm-50mm |

| Total installation power | 31KW |

| Actual production power | 22KW |

| Air consumption | 0.4m³/min |

| Supply voltage | 380V,50HZ |

| Machine weight | 3500kg |

| Size(L*W*H) | 3050mm*1270mm*2000mm |

6.Cap slitting machine

| Cap diameter | 18mm-60mm |

| Cap height | 12mm-50mm |

| Capacity | 15000-20000 pcs / hr |

| Total installation power | 1KW |

| Actual production power | 0.7KW |

| Air consumption | 0.5m³/min |

| Supply voltage | 220V,50Hz |

| Machine weight | 200KG |

| Size(L*W*H) | 1700mm*820mm*1280mm |

Spare part list

| MACHINE | SPARE PART | QUANTITY | UNIT | |

| Plastic cap molding machine (Hydraulic) | Mold system | Additional Mold | 2 | set |

| Mold Spring | 5 | pcs | ||

| Mold Nut | 6 | pcs | ||

| Interlocking bar | 2 | set | ||

| Linkage spring | 4 | pcs | ||

| Linkage copper sleeve | 3 | pcs | ||

| Linkage bearing | 1 | pcs | ||

| Scraping knife base | 2 | pcs | ||

| Scraping knife | 4 | pcs | ||

| Hand operated wrench | 1 | pcs | ||

| Manual extrusion sleeve | 1 | pcs | ||

| Tool Box | 1 | set | ||

| Mold maintenance pack | 1 | set | ||

| Hydraulic system | Oil cylinder | 1 | pcs | |

| Oil valve | 1 | pcs | ||

| Oil tube | 4 | rope | ||

| U ring | 20 | pcs | ||

| Oil nozzle | 5 | pcs | ||

| oil seal | 10 | pcs | ||

| Air system | Air tube | 2 | rope | |

| Air tube adapter | 6 | pcs | ||

| Air gun | 1 | pcs | ||

| Heating system | Heating Ring | 3 | pcs | |

| thermocouple | 5 | pcs | ||

| electronic system | Solenoid valve | 1 | pcs | |

| Solid state | 1 | pcs | ||

| Intermediate relay | 2 | pcs | ||

| Cooling system | Water nozzle | 5 | pcs | |

| Chiller adapter | 2 | pcs | ||

| water pipe | 1 | pcs | ||

| Plastic cap slitting machine | Blades | 5 | set | |

| Heating Rod | 2 | pcs | ||

| Punch | 2 | pcs | ||

Doser Technical configuration:

| Motor power | 0.31kw |

| Output capacity | 0.1-10kg/hr |

| Material type | Granule |

| Control type | 0~10V extruder inverter signal |

Auto loader Technical configuration:

| Conveying capacity | 200kg/hr |

| Hopper capacity | 3L |

| Hopper dimension | 595*345*355 |

| Material level control | Microswitch |

| Motor power | 1.15-1.32kw |

| Material type | Granule |

7.Chiller 5HP air type

Main technical configuration

| No. | Main technical configuration and parameters | YDL-5F |

| 1 | compressor | DAKIN (Japan) |

| 2 | evaporator | Shell and tube type (stainless steel shell and tube, stainless steel heat exchange tube) |

| 3 | expansion valve | Alco (United States) |

| 4 | filter | Alco (United States) |

| 5 | Water pump | CNP (China) |

| 6 | Pressure controller | FENSHENG(China) |

| 7 | water pressure gauge | CK (Taiwan of China) |

| 8 | High and low pressure gauges | SK (Taiwan of China) |

| 9 | Fan | Weima (Shanghai) |

| 10 | AC contactor | schneider |

| 11 | thermal relay | schneider |

| 12 | temperature control | Microcomputer LCD digital display (dual display of actual temperature and set temperature) |

| 13 | structure | Box type integral type |

| 14 | Surface Treatment | Powder coating |

| 15 | Water tank form | Stainless steel insulation type |

| 16 | Temperature Control Range | 7~35℃ |

| 17 | refrigerant | R22 |

| 18 | Protector | Compressor overload protection/high and low pressure protection/water cut-off, water shortage protection/phase sequence protection/water pump overload/fan overload protection |

Performance parameters of YDL-5F air-cooled box type industrial chiller unit

| Unit model | YDL—5F | |||

| Cooling capacity | 13.5Kw | |||

| 11610Kcal/hr | ||||

| Use power supply | 3N-380V±10%:50Hz±2% | |||

| Whole machine input power | Kw | 5 | ||

| compressor | type | Fully enclosed vortex type | ||

| Qty | sets | 1 | ||

| Input power | Kw | 3.75 | ||

| chilled water | Inlet water temperature | ℃ | 12 | |

| Outlet temperature | ℃ | 7 | ||

| Flow | m3/h | 2.5 | ||

| Pipeline specifications | mm | DN65 | ||

| condenser | Type | Efficient copper tube and aluminum foil tightly expanded finned heat exchanger | ||

| fan | Input power | Kw | 0.5 | |

| electric current | A | 1.5 | ||

| chilled water pump | Type | Stainless steel horizontal centrifugal pump | ||

| Input power | Kw | 0.55 | ||

| flow | m3/h | 3.6 | ||

| External lift | Mh2O | 19.5 | ||

| External dimensions | length | mm | 1420 | |

| width | mm | 660 | ||

| height | mm | 1200 | ||

| Nominal capacity of water tank | L | 70 | ||

| Unit weight | kg | 250 | ||

8.Screw Low Pressure Air Compressor

| Model | DMG-30F |

| Power(kw) | 30 |

| Discharge pressure(mpa) | 1.0 |

| Capacity(Nm³/min) | 4.4 |

| Noise | 63±2 |

| Output diameter | 1/4# |

| Size(mm) | 1150*800*1280 |

| weight(kg) | 550 |

Diesel Generator Set:GB-SC375

| Standard features | |

| MODEL | GB-SC375 |

| Standby power (50HZ) | 330KW/412KVA |

| Prime power(50HZ) | 300KW375KVA |

| Engine | SDEC POWER SC12E480D2 |

| Alternator | GB POWER GB-HCI444F |

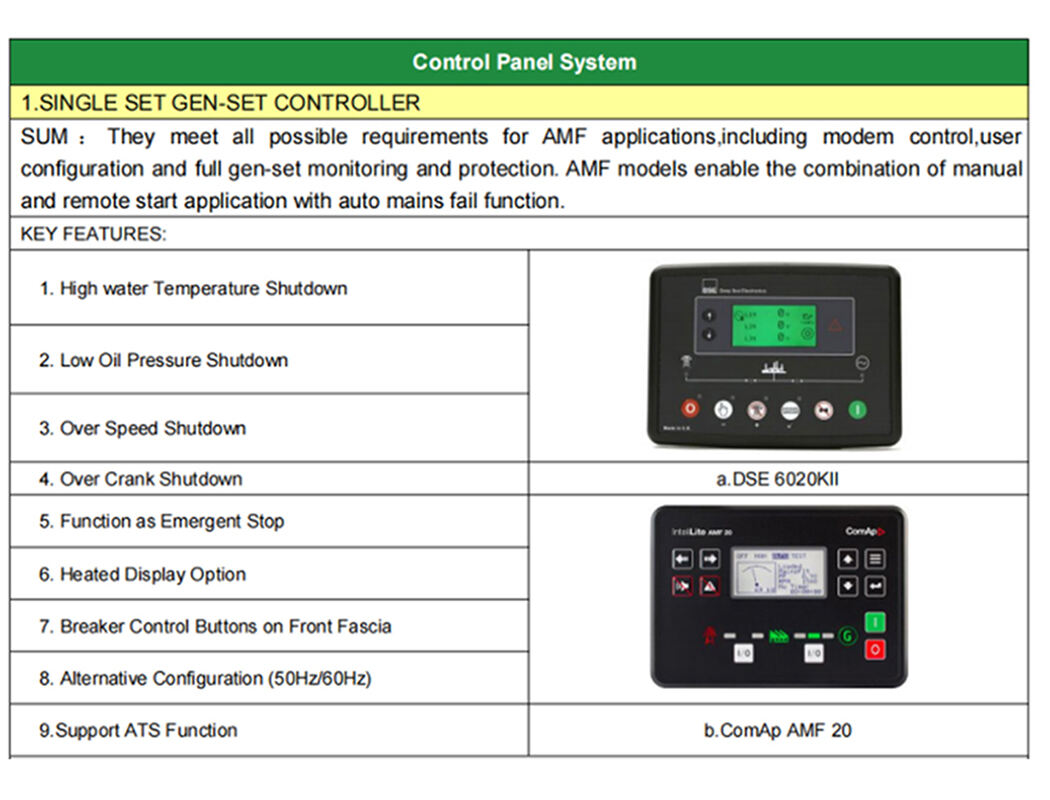

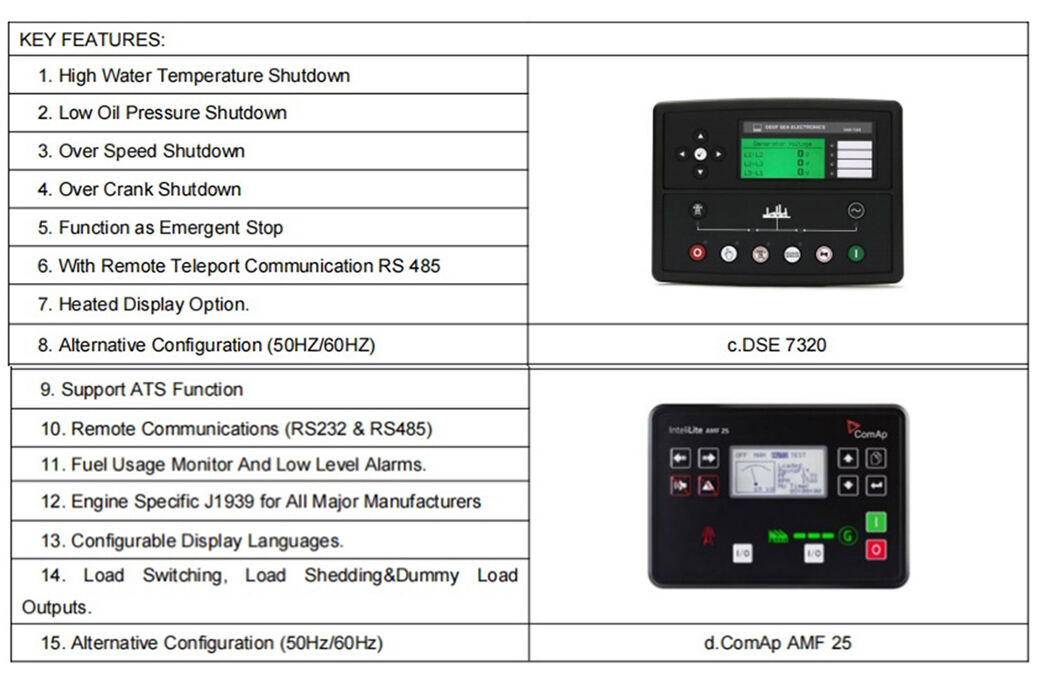

Standard control panel, Including controller, Operation lighting, Emergency stop button, Buzzer

Main line circuit breaker

Two 12V free maintenance battery, battery charger, Battery Ract and Battery Switch

Industrial silencer, Ripple Flex exhaust pipe, Flange

Fork lift position and lifting position

With-8 hours Base Fuel Tank; Fuel Tank Capacity: 550L

Radiator 50℃ max, Fans driven by Belt, with safety Guard

Hand pump special for take out dirty oil

| Generator Set Ratings | ||||||

| Voltago | Frequoncy | Phase | P.F (cOSΦ) | Prime Current Amps | Standby Power (KW/KVA) | Prime Power (KW/KVA) |

| 440/254 | 50 | 3 | 0.8 | 493 | 330/412 | 300/375 |

| 415/240 | 50 | 3 | 0.8 | 522 | 330/412 | 300/375 |

| 400/230 | 50 | 3 | 0.8 | 541.5 | 330/412 | 300/375 |

| 380/220 | 50 | 3 | 0.8 | 570 | 330/412 | 300/375 |

Prime Power(PRP):Prime power is available for an unlimited number of annual hours in variable load application, in accordance with GB/T2820-97 (eqvlSO8528);10% overload capability is available for a period of 1 hour within a 12-hour period of operation.

Standby Power Rating (STP):The standby power rating is applicable for supplying emergency.

| Dimension & Weight Of Generator Set | |

| Dimension(L*W'H)/CM For Open Type | 320x119x212 CM |

| Net Weight/KG For Open Type | 3200 KG |

| Dimension(L*W'H)/CM For Silent Type | 450x154x208 CM |

| Net Weight/KG For Silent Type | 4100 KG |

| Dimension (L-'W'H)/MM For Trailer Type | |

| Net Weight/KG For Trailer Type | |

| Specification of Engine | ||

| Basic Specification | Engine Model | SC12E480D2 |

| Manufacturer | SDEC POWER COMPANY | |

| Prime Power | 323KW/430HP | |

| Standby Power | 355KW/473HP | |

| Engine Configuration | 6Cylinder In Line,4Stroke,Direct Injection | |

| Gas Feeding Model | Turbo Charged | |

| Borex Stroke | 135x165(MM) | |

| Displacement | 14L | |

| Rated Speed | 150ORPM | |

| Speed Governor | Electric Governor | |

| Starter Model | 24V DC Start | |

| Cooling System | Water Cool | |

| Compression Ratio | 16.3:1 | |

| Exhaust System | Exhaust Gas Flow | 1150L/s |

| Exhaust Temperature | 497℃ | |

| Max Back Pressure | 10kPa | |

| AirIntake System | Max Intake Restriction | 6.2kPa |

| Burning Capacity | 510L/s | |

| Air Flow | 8180L/s | |

| Fuel System | Fuel Consumption (Prime Power 100%) Load | 59.1L/H |

| Fuel Consumption (Prime Power 75%) Load | 44.5L/H | |

| Fuel Tank Capacity | 550L | |

| Lubrication System | Oil Capacity | 38.6L |

| Oil Consumption | ≤0.24L/h | |

| Oil Pressure at Rated RPM | 241-345kPa | |

| Cooling System | Total Coolant Capacity | 63.9L |

| Themostat Open Temperature | 82-93℃ | |

| Max Coolant Temperature | 100℃ | |

| Specification of Alternator | ||

| Basic Specification | Alternator Model | GB-HCI444F |

| Manufacturer | GB POWER company | |

| Prime Output | 300KW/375KVA | |

| Standby Output | 330KW/412.5KVA | |

| Excitation Model | Brushless, Self-Exciting | |

| Cooling Method | Air Cooling | |

| Connection Type | 3 Phase and 12 Wires "Star"Connection | |

| Power Factor | 0.8 | |

| Protection Class | IP23 | |

| Insulation Class | H | |

| Altitude | ≤1000m | |

| Voltage Regulation, Steady State | ≤±1% | |

| Telephone Infiluence Factor | <50 | |

| Sudden Voltage Warp (100% Sudden Reduce) | ≤±1% | |

| Sudden Voltage Warp (Sudden Increase) | ≤±25% | |

| Voltage Stable Time (100% Sudden Reduce) | ≤6S | |

| Voltage Stable Time (Sudden Increase) | ≤6S | |

| Frequency Reduce | 0-5% adjustable | |

| Frequency Regulation, Stead State | ≤1.5% | |

| Frequency Waving | ≤0.8% | |

| Sudden Frequency Warp (100% Sudden Reduce) | ≤+12% | |

| Sudden Frequency Warp (100% Sudden Increase) | ≤-10% | |

| Frequency Recovery Time (100% Sudden Reduce) | ≤5S | |

| Frequency Recovery Time (Sudden Increase) | ≤5S | |

| Compliance GB755,BS5000,VDE0530,NEMAMG1-22,IED34-1,CSA22.2 and AS1359 Stands | ||

POWER STABLIZER 600KVA

MODEL:TNSZ-600

Rated capacity:600KVA

Output current:912A

Number of phases:3

Frequency:50HZ

Input Voltage:304-456V

Rated output voltage:380V

Accurate voltage regulation:±5

Size:1420*1090*2310mm