Introduction to Liquid Filling and Sealing Machine

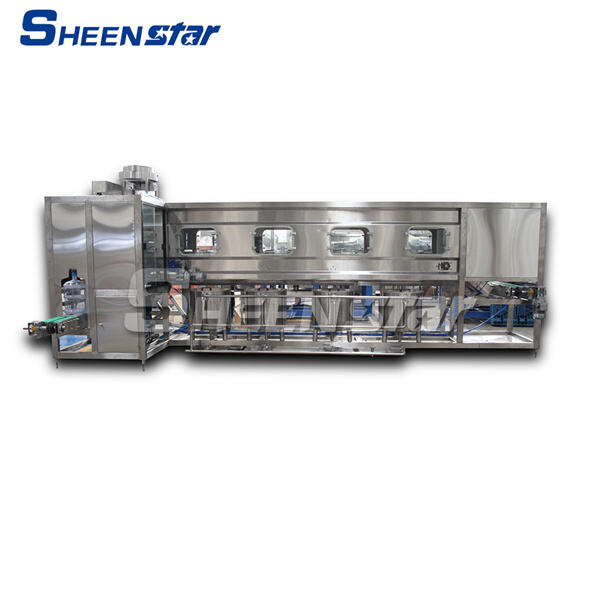

Quickly Liquid Filling and Sealing Machine is a used instrument to fill fluids, such as juices, sodas, and more beverages, into bottles or pouches and then sells them to stop any leakage. This Sheenstar liquid filling and sealing machine is particularly beneficial when you look at the beverage and foodstuff industry, whenever it might mass-produce and bundle different beverages quickly and effectively.

You will find a couple of advantages to using a Liquid Filling and Sealing Machine. Firstly, it saves work and time since it could fill and seal multiplied containers. Next, it indicates that the liquid is filled precisely without the wastage or spillage. Thirdly, Sheenstar bottle filling and sealing machine helps to keep the quality associated with an item, as it guarantees which the known right levels of liquid are filled and sealed correctly.

One of the most notable innovations for the Liquid Filling and Sealing Machine is automation. This unit could be programmed to play different functions, like filling, capping, and sealing. This automation function implies that the quality of the item is maintained, as the chance is reduced by people’s mistake.

Safety is vital when it comes to using any machine. The Liquid Filling and Sealing Machine is designed and several safety qualities to ensure the safety related to consumer and product. The Sheenstar filling and capping machine is built with sensors that may detect any abnormalities during the filling process, for example overfilling or under filling. In addition, incorporates the functional system that may identify and alarm any machine malfunctions, which can prevent accidents and injury to the machine.

Using a Liquid Filling and Sealing Machine is effortless and simple. Firstly, the Sheenstar liquid filling and capping machine needs to feel ready up and configured relating to the needs you have. Including programming the machine to fill the proper quantity of liquid, sealing power, and container size.

As soon as the machine is arranged, the containers are then loaded on the machine, and the filling procedure could begin. The liquid is poured into your container through the valve or nozzle, which operates immediately during the filling process. The sealing process then takes place, that could be achieved either with heat sealing or cold sealing based on the desires associated with the manufacturer.

The quality associated with the machine is as essential as the functionality. Whenever purchasing the Liquid Filling and Sealing Machine, it is important to choose a machine which is durable, efficient, and dependable. It is important to pick a brand that produces quality after-sales service, like maintenance, repair, and technical help.

You will find a few applications for Liquid Filling and Sealing Machines, like the foods and beverage industry, aesthetic, and companies that can easily be pharmaceutical. This Sheenstar automatic filling and capping machine is suitable for businesses looking for the mass-production and packaging efficient system, dependable, and cost-effective.

Sheenstar over 15 Liquid filling and sealing machineof experience the beverage machinery industry and has integrated production, R and D, after-sales sales services, accredited though ISO9001, CE, SGS and many other certifications. Our team of experts will design the ideal machine for each client based on research the market, inquires and budget. Our customers completely satisfied with the equipment and service provided by our business. We have earned a respectable name in the industry of drinking and water equipment.

From procurement of raw Liquid filling and sealing machineto manufacturing production Our company has a knowledgeable and experienced quality inspector team. The quality department our company is always in charge of each step in order to make sure that all equipment in compliance with the highest quality standards. Materials are SUS304/SUS316 of top quality, easy clean and have an extended life. The electrical components are famous brands, which have excellent quality, excellent service, after-sales assistance.

Sheenstar offers complete range of beverage production systems, including pure water fruit drinks, oil, soymilk, wine, yogurt. Liquid filling and sealing machinemay be made of glass bottles, plastic bottles, 5 gallon barrels cans. The entire line comprises water treatment system, beverage pre-treatment system, injection molding machine bottle-making machine, refilling filling machine packaging machine, other related machines.

Customization options available to meet the requirements of our customers. We can supply layout diagram for the factory along with the bottle's label. We will also provide Liquid filling and sealing machine of production during the production process of the machine. Additionally, we have a professional after-sales service department can provide quick and thorough technical support. The engineers will visit the customer factory install and test the machines' operation and train the workers in the proper use of and maintenance of machines, ensuring the normal operation of the equipment as well as the smooth process customer production.