The Incredible Automatic Bottle Filling and Capping Machine: A Game-Changer in Contemporary Production

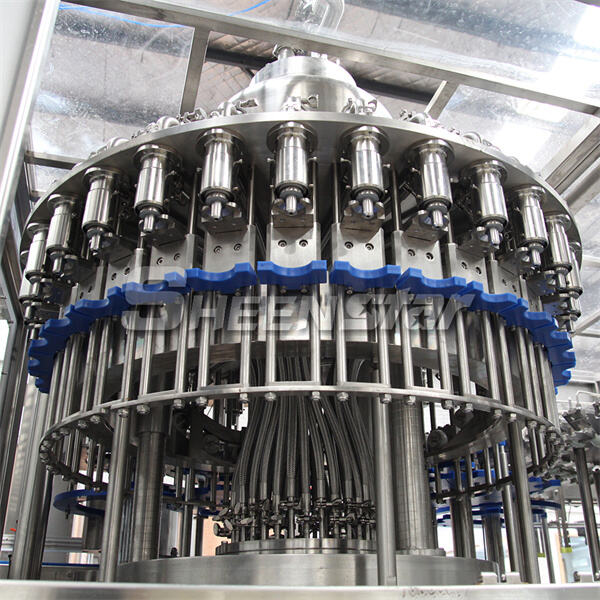

In the society of automation crucial production existing, one system like the bottling market will be the Automatic Bottle Capping Machine and Filling. This Sheenstar automatic bottle filling and capping machine gadget is a useful functional body is practical instantly fills up compartments along with various liquids and caps all of them at an extremely quick price.

The automated Bottle Filling and Capping Machine are very efficient and offer numerous advantages for manufacturing. Firstly, Sheenstar filling and packaging machine saves time and effort. This product revolutionizes the process and completes it faster than humans could, reducing labor hours and increasing efficiency in the workplace.

The advancement of technology has transformed Automated Bottle Filling and Capping. Sheenstar filling and capping machine have seen significant advancements that greatly enhance efficiency. Some of the recent developments include the ability to fill and cap at higher speeds, increased filling capacities, and compatibility with various bottle types, sizes, and caps. They can handle different types of liquids, sizes, and caps.

Safety is a paramount concern for manufacturers and consumers alike. Sheenstar bottle filling and capping machine are designed to be safe to use and operate. They feature safety mechanisms such as automatic stops in case of overfilling, automatic limit setting and detection, and sensor-based systems to detect any abnormal operations. Manufacturers also need to adhere to strict regulations and guidelines to ensure the product is safe and reliable.

Using an Automated Bottle Filling and Capping Machine is straightforward. Firstly, power up the Sheenstar filling and packaging machine by connecting it to the power source. Then, prepare the bottles and caps, ensuring they are clean and of the correct size and type. Place the bottles on the conveyor system, and the machine will automatically fill them with liquid and cap them. Finally, perform a quality check to ensure properly capped and filled bottles.

Customization services are available Automatic bottle filling and capping machine the requirements our customers. We can provide an industrial layout diagram, design bottle and label. We can also provide an outline of the process. We also have a group of experienced technicians that can provide timely and efficient assistance. Engineers visit customer factory install test operating the machines and help the employees on how to use and maintain machines properly to ensure the proper operation of the equipment and the seamless advancement of the production process for our customers.

Sheenstar 15 Years rich experience in beverage machinery industry which includes production, R and D, after-sales sales Automatic bottle filling and capping machineand is accredited through ISO9001, CE, SGS as well as other certifications. We design and build the right machines to meet the needs of customers based upon the market research, inquiry and budget. Customers of Sheenstar are very satisfied the products and services that we provide. are a well-known reputation in the business of beverage and water machines.

We have a Automatic bottle filling and capping machineskilled quality inspection team,from raw material procurement to manufacturing production. Our quality inspection department always is on the lookout for every detail ensure that every equipment has the highest standards of high-quality requirements. Materials are SUS304/SUS316 of top quality, easy to clean has longevity. The electrical components are world famous manufacturers, good quality, excellent service and after-sales services.

Sheenstar offers complete range of beverage manufacturing solutions, such pure water, juice from fruits carbonated drinks, oil, wine, soy milk yogurt and more. Contianers may made of glass bottles, plastic containers, 5 gallon barrels cans. The entire line includes water treatment system, beverage pre-treatment system, injection molding machine bottle making machines, refilling filling machine labeling system, packing Automatic bottle filling and capping machine, and various other auxiliary machines.

Quality and service are crucial aspects of Automated Bottle Filling and Capping. Manufacturers must provide excellent customer support to ensure the product functions smoothly and reliably. Additionally, the Sheenstar bottle filling and sealing machine product's quality must be top-notch to ensure it produces high-quality products consistently.

Automated Bottle Filling and Capping machines have various applications across industries such as food and beverage, pharmaceuticals, chemicals, and cosmetics. They can fill and cap bottles with liquids, creams, gels, powders, and other products. These versatile machines can adapt to different product requirements and packaging needs.

The Automated Bottle Filling and Capping Machine are indispensable in manufacturing operations. They enhance efficiency, reduce errors and production costs, are safe to use and operate, and offer a wide range of capabilities. With the latest advancements in technology, Automated Bottle Filling and Capping Machine continue to revolutionize the bottling industry.