Sick to death of buying water bottles all the time but can’t trust that your consumption is safe every single time you drink it like a yo-yo? Then you need a water bottle plant machine. Yes, own a Sheenstar water bottle filling machine today. In this article, I will discuss the following benefits, innovation, precaution, and its usage of how a water bottle plant machine should be operated as well how to maintain it to work smoothly.

BENEFITS OF WATER BOTTLE PLANT MACHINES.

Having a water bottle plant machine saves you a lot of money. You don’t have to buy a water bottle every day; you just need to refill your bottle in the machine in a short time. A water bottle plant machine has lots of plastic bottles, meaning, if we completely stopped taking one, we would reduce most of the plastic bottles. Also, another benefit is a water bottle plant machine is that it is portable. You don’t have to worry again about the water running and the heavy bottles. An important use of this machine is that it can always provide you with clean and safe water.

A water bottle plant machine is one of the best innovations that has happened. Sheenstar mineral water plant machine a lot and remove all the impurities so that you can drink your water in its finest form. It makes your drinking sparkling water, which was not possible, as only still water was recommended. Water plant bottle machine has been a user-friendly operation.

No need to fret; all this is safe because private Equity owns this water bottle plant machine. Each and every one of these machines, for example, embarks on a very distinct multi-staged filtration process that gradually gets rid of things like bacteria, viruses, or other chemicals responsible for making bottled water unsafe for our health. How do you know if the water is contaminated or not? Conversely, they undertake regular maintenance checks to maintain machine operation, quality, and provide a consistent and high-quality output of water. You just need to slide in it, fill up a water bottle machine with tap water and let the machine’s filters do all the work and cleanse this H2O. After the entire purification process, you could use this water either in your bottle or to fill a glass and drink. For starters, the machine will require some maintenance to operate effectively, with servicemen conducting maintenance on the assembly, such as filter replacement, leak checks, or thorough cleaning. Only highly skilled personnel are entrusted with the maintenance of the machine, taking into account the exemplary safety and operational maintenance standards. Put plainly, the water produced by the water bottle plant machine is always of the highest quality. Each and every one of these machines, for example, makes use of best-in-class filtration technology that ensures that water has been filtered through its thorough cleaning process guaranteed to rid it of impurities and things that sit between clean and safe water. For instance, regular servicing reminds the population of their commitment to the provision of superior quality water.

Usage Centers of Water Bottle Plant Machines’ Inclusivity Water bottle plant machines can be used in any area, including homes or small businesses among others. These machines are crucial in areas where water is of low quality and where there is no reliable water supply. In addition, those who drink soda can also rely on it for nutrition supplements hence inclusive.

One of the biggest advantages to owning a water bottle plant machine is that you can save tons of money. No longer pay for daily bottled water purchases as you can simply refill your own bottle in this machine. The water bottle plant machine also allows reduces the number of plastic bottles that plague our planet seeing as you have cut down on your intake completely. Also, let's not forget the ease of using one - gone are the days when we need to fret about our water supply running out and forgetting heavy bottles. The most important use of this machine is to provide you with clean and safe water all the time.

Innovative Water Bottle Plant Machines

Water bottle plant machines have been an innovative revolution in the safe drinking water access space. They utilize the latest filtration technology to remove any impurities and ensure your water is at its purest form. In addition, they had a special feature - They made sparkling water as well- something that was not possible using traditional dispensing of plain drinking water. As a user-friendly operation, water bottle plant machines have served division for both household and commercial reasons.

Do not worry, private Equity owned water bottle plant machine is safe. All these machines undertake a very particular multi-staged filtration process that slowly eliminates elements like bacteria, viruses or even chemicals in charge of contaminating the water and thus making it unsafe for our health. On the flip side, regular maintenance checks are carried out to maintain operational efficiency ensuring a consistent and high-quality output of water.

How to Use Water Bottle Plant Machines

Using a water bottle plant machine is as simple. Just slide in the machine, pour tap water into it and let filters cleanse H2O. Once it has gone through the whole purification you can refill your own bottles or choose to pour a glass and immediately drink water.

Taking Care of Water Bottle Plant Machines

The effective working of water bottle plant machines hinge on proper maintenance. Regular servicing is required for the maintenance of these units which includes filter replacements, leak checks and routine cleaning. The intensive servicing tasks are handled only by trained professionals and adhere to strict quality, safety and operational standards.

Water bottle plant machines produce water that always adheres to an extremely high level of pristine quality. This Sheenstar bottle water machine employs the best in class filtration technology to ensure complete elimination of impurities from water which is needed for it to turn safe and drinkable. Servicing regularly also serves to remind them of the dedication to deliver superior water.

We have a Water bottle plant machineskilled quality inspection team,from raw material procurement to manufacturing production. Our quality inspection department always is on the lookout for every detail ensure that every equipment has the highest standards of high-quality requirements. Materials are SUS304/SUS316 of top quality, easy to clean has longevity. The electrical components are world famous manufacturers, good quality, excellent service and after-sales services.

Sheenstar has 15 Years rich Water bottle plant machinein the field of beverage machinery includes production, R and D, sales and after-sales service certified through ISO9001, CE, SGS various other certifications. We can set up the best machines customers based on the market research, inquiry, and budget. The customers are very satisfied with products and services. Sheenstar has outstanding reputation in the beverage and water machinery sector.

We provide personalized customization services allows us to customize filling machine solutions based on the Water bottle plant machine needs of customers. We will provide a factory layout diagram as well as the bottle's design and label. We can also provide a production schedule during the production process of the machine. Additionally, we have a professional team of technicians can provide timely and thoughtful support. The engineers will visit manufacturing facility the customer to install, test and run the equipment. They also will train workers on how to operate and maintain the equipment. This ensures the smooth operation of the equipment, and progress of the production.

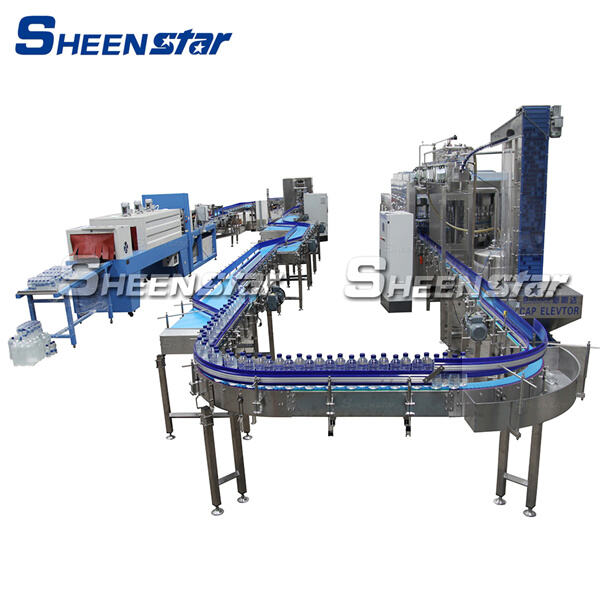

Sheenstar offers complete range of beverage manufacturing solutions, such pure water, juice from fruits carbonated drinks, oil, wine, soy milk yogurt and more. Contianers may made of glass bottles, plastic containers, 5 gallon barrels cans. The entire line includes water treatment system, beverage pre-treatment system, injection molding machine bottle making machines, refilling filling machine labeling system, packing Water bottle plant machine, and various other auxiliary machines.

Water bottle plant machines are versatile and useful for many settings like homes, small businesses, schools, healthcare facilities. These machines are especially useful in regions with bad water and availability of clean drinking water. Moreover, its ability to make soda nutritional supplements it an option for those who like sodas as well.