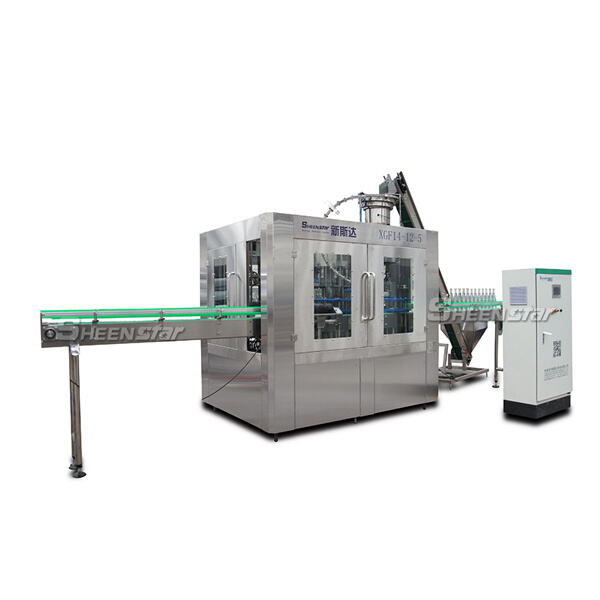

The Amazing Auto Liquid Filling Machine.

Do you wish to increase efficiency and lessen the workload in your production company? Do you need to ensure product quality and security while reducing errors within the production line? An auto liquid filling machine may be the perfect tool you. This Sheenstar liquid filling machine is a revolutionary innovation has changed the manufacturing industry for the better.

The auto liquid filling machine has numerous advantages. First, it is faster and a lot more efficient than manual filling, reducing the right time to fill containers. Second, this machine ensures that every container is filled to your exact amount desired, ensuring product constant quality. Third, Sheenstar filling machine really is less labor-intensive, reducing the workload on employees and saving the ongoing company money in salaries. Finally, it minimizes waste, ensuring that every fall of liquid is put to make use good of.

Perhaps one of the most innovative popular features of the auto liquid filling machine may be the control computerized system. This method monitors the entire filling procedure ensuring that each container is filled into the exact amount with just minimal waste. Additionally it is designed with sensors that detect any abnormalities in the filling process and automatically stop the operation if it has a problem. This Sheenstar automatic filling machine particular aspect really helps you to prevent errors and ensure the security of the filling process.

Safety is a top priority it comes towards the manufacturing process, and the auto liquid filling machine satisfies this requirement. With this machine, operators are less confronted with the chemical substances and properties of the liquid being filled, decreasing the potential for accidents or incidents. The Sheenstar automated filling machines also equipped with safety guards to avoid the operator from getting into contact with the machinery.

Using the auto liquid filling machine is simple. The Sheenstar operator simply does need to program the machine with the required parameters including the amount of liquid to be filled, and the filling speed. As soon as programmed, the machine can fill containers automatically, minimizing individual intervention the chance of human error. To use the machine, you need to press the start switch, and the machine does the others.

Sheenstar offers complete Auto liquid filling machineproduction systems, including pure water, fruit drinks, wine, soymilk, oil, yogurt. Containers made plastic, glass barrels of 5 gallon cans. The entire line comprises water treatment system, beverage pre-treatment system, injection molding machine and bottle-making machine, refilling filling machine, labeling system, packing machine, other machinery.

From the procurement raw materials to Auto liquid filling machineand production We have highly skilled and highly experienced quality inspection team. Our quality inspection team strictly controls every step ensure that each piece of equipment exceeds the highest quality requirements. The components are top quality SUS304/ SUS316, which are easy to clean and has extended life span, and the electrical components are made by a famous brand which have good quality and a good after sales service.

We offer Auto liquid filling machine service that allow us to tailor filling solutions the particular requirements of our clients. We can offer a factory layout diagram along with the bottle's label. When the machine is in production, we will also supply a production schedule. At the same time, we have a professional after-sales service team that can provide prompt and professional technical assistance. Our engineers will visit customer factory install test the machines and instruct the employees on how to use and maintenance machines correctly making sure that they operate in a normal manner the equipment as well as the smooth advancement of the production process our customers.

Sheenstar has 15 Years rich Auto liquid filling machinein the field of beverage machinery includes production, R and D, sales and after-sales service certified through ISO9001, CE, SGS various other certifications. We can set up the best machines customers based on the market research, inquiry, and budget. The customers are very satisfied with products and services. Sheenstar has outstanding reputation in the beverage and water machinery sector.

Using the auto liquid filling machine is uncomplicated. It comes with an user-friendly interface helps it be an easy task to program and run. First, put up the machine and verify it is in the position that's right. Then, Sheenstar auto filling machine program the machine utilizing the desired settings, for example the total amount of liquid to be filled and the filling speed. As soon as programmed, the machine can run automatically, with minimal human intervention.

The auto liquid filling machine is a reliable machine that will require minimal maintenance. However, regular maintenance is essential to help keep the machine running at an optimal level. The company provides service manuals with instructions on the best way to maintain and repair the machine. Additionally, the Sheenstar filling packing maker offers excellent customer, answering any relevant questions or concerns relating to the machine.

Quality is an essential element of, and the auto liquid filling machine excels in this aspect. It really is built with high-quality materials that ensure durability and strength, ensuring the machine lasts a right long time. The Sheenstar control system is also quality high ensures consistent and accurate results.