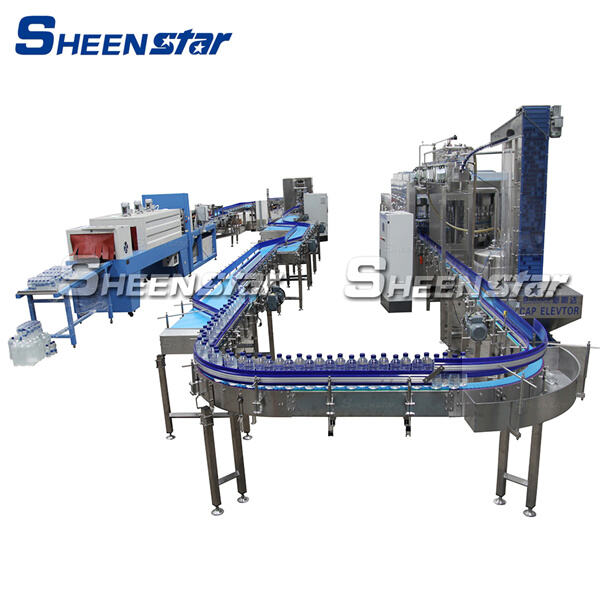

We can see how filling lines are essential in ensuring proper bottling and packaging. We at Sheenstar strive for a seamless process when filling out lines. So now, let’s see how filling this lines can help us do things correctly!

When we are talking about efficiency, we are talking about doing things faster to not waste time. With a filling line, we can ensure that there is the proper amount of everything and that each bottle or pack is filled properly. This is helpful in completing our work faster and without errors. And it also frees then time and energy so we can do more things!

Sheenstar uses the latest technology to ensure we have the most optimized filling line. It means that everything works in automotiv mode seamlessly. Our filling line system puts the production process faster and better. This allows us to get more done than eve…

We can produce more, while wasting less with filling line technology. It allows us to fill those bottles and packages more quickly, and as a result get more work done. With this technology, we ensure that we do not waste either material or products. This helps us avoid wasting money and resources, which is awesome!

Their products should be awesome, dope, whatever, ok? With an effective filling line, we can fill every single bottle/package each time! This ensures we have a high-quality product, which is necessary for our customers. A dependable filling line guarantees our products match up beautifully, always and ready!

We save money — and do more work — by having a well-designed filling line. This allows us to accomplish more in shorter bursts with less effort. A good filling line ensures we stay on track and ready to go. It also helps us reduce costs and streamline our productivity, which is crucial to our business.

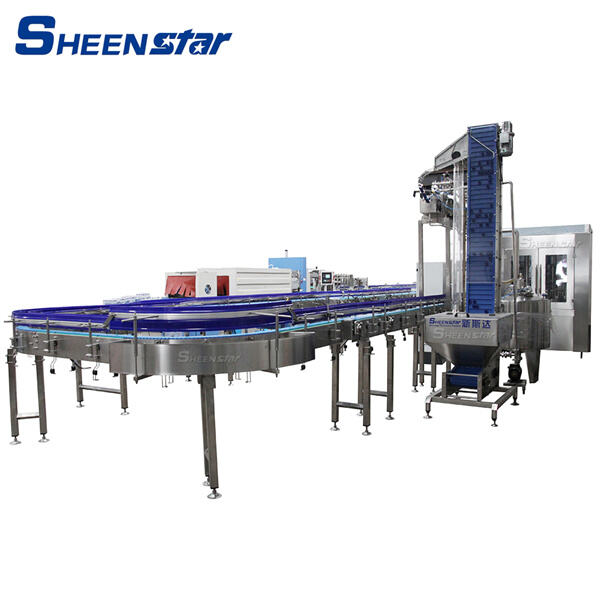

From procurement raw materials all the way to manufacturing and production our skilled experienced quality inspection team. The quality department within business is constantly filling lineevery step in order to make sure that the equipment used is up to high quality standards. Materials are SUS304/SUS316 of top quality, easy clean, with a long life span. The electrical components famous brands, which have excellent quality, good service and after-sales service.

Sheenstar is a 15-year old business vast experience in the field of filling linemachinery. We provide production, R and D sales, sales, and after-sales services, and are accredited ISO9001, CE and SGS certifications. We will configure suitable machines for our customers based on the market research, inquiry, and budget. Customers highly satisfied with the equipment and services. Sheenstar has outstanding reputation in the water and beverage machinery sector.

Sheenstar offers complete range of beverage manufacturing solutions, such pure water, juice from fruits carbonated drinks, oil, wine, soy milk yogurt and more. Contianers may made of glass bottles, plastic containers, 5 gallon barrels cans. The entire line includes water treatment system, beverage pre-treatment system, injection molding machine bottle making machines, refilling filling machine labeling system, packing filling line, and various other auxiliary machines.

Customization services are available filling line the requirements our customers. We can provide an industrial layout diagram, design bottle and label. We can also provide an outline of the process. We also have a group of experienced technicians that can provide timely and efficient assistance. Engineers visit customer factory install test operating the machines and help the employees on how to use and maintain machines properly to ensure the proper operation of the equipment and the seamless advancement of the production process for our customers.