Mesin Pengisian dan Pencetakan Label Botol: Jawaban Lengkap untuk Masalah Pengisian atau Pencetakan Label Botol.

Bosan mengisi dan mencetak label botol satu per satu, yang bisa memakan waktu berjam-jam? Memang, di dunia yang ideal proses ini diotomatisasi melalui mesin pengisian dan pencetakan label botol. Dalam blog ini, kita akan membahas keuntungan menggunakan mesin tersebut, fitur-fitur yang membuatnya berbeda dari printer lain seperti protokol keselamatan yang harus diikuti dan bagaimana Anda dapat menjaga kualitas saat mendesain dengan mesin-mesin canggih ini.

Mesin-mesin ini untuk pengisian dan penempelan label botol memberikan kenyamanan maksimal bersama dengan efisiensi. Mesin-mesin ini membantu mengisi dan menempelkan label pada beberapa botol dengan menghilangkan waktu yang lebih lama yang dibutuhkan untuk tenaga kerja manual, sehingga pada akhirnya menghemat biaya selama produksi. Keterampilan ini berarti bahwa mereka dapat beralih dengan cepat antara berbagai jenis botol dan mengisi setiap botol sesuai yang diperlukan setiap kali.

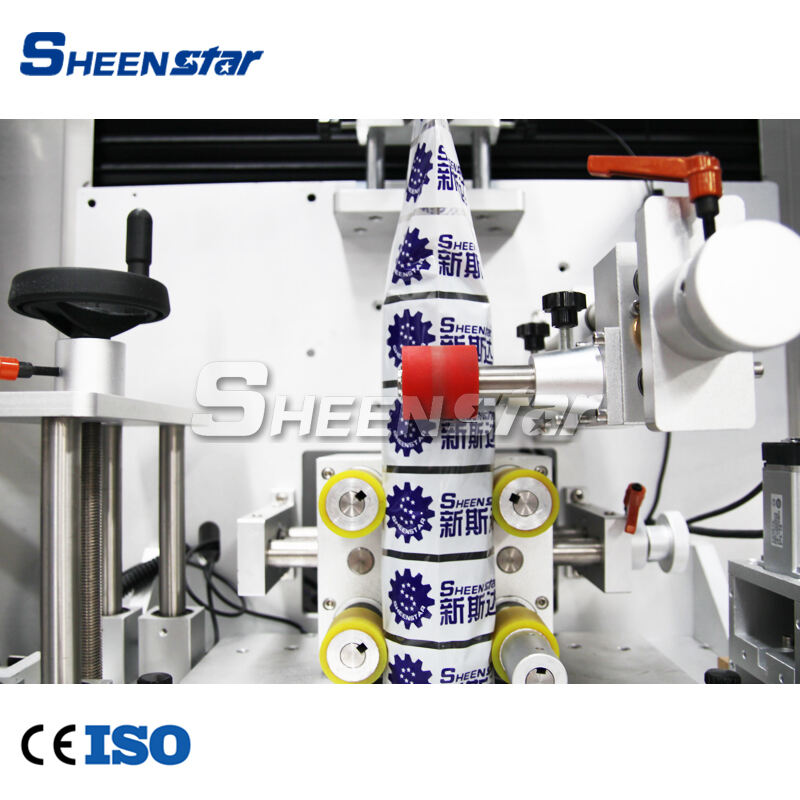

Beberapa fitur utama dalam mesin pengisian dan penempelan label botol adalah kontrol layar sentuh inovatif, kemajuan sistem otomatis, dan ketepatan pengisian unik yang ditemukan pada model-model modern hari ini. Dibuat dari komponen terbaik, mesin-mesin mereka tidak hanya tahan lama tetapi juga sangat kokoh dan tangguh.

Untuk alasan keselamatan, mesin pengisian dan penempelan label botol dirancang agar aman sepenuhnya dengan beberapa sensor yang langsung menghentikan operasi jika terjadi kegagalan tunggal. Penutup keselamatan tambahan melindungi operator dari mendekati bagian mana pun yang bergerak selama operasi.

Cara Mengoperasikan Mesin Pengisian dan Penempelan Label Botol dalam 7 Langkah

Mesin pengisian dan penempelan label botol sangat ramah pengguna. Diperlukan untuk memastikan mesin telah disetel dengan benar. Isi corong dengan produk yang diinginkan, lalu muat botol-botol kosong ke dalam mesin ini. Duduk santai dan amati saat mesin tersebut mengisi setiap botol dengan akurat. Label yang digunakan juga mudah digunakan, cukup muat label yang benar ke dalam mesin, pastikan label itu sejajar dengan wadah atau barang lain yang ingin diberi label, lalu tekan Lanjutkan Membaca

Mesin pengisian dan penempelan label botol, seperti semua mesin di sekitar kita, membutuhkan pemeliharaan rutin agar tetap memberikan yang terbaik. Perhatikan semua bagian untuk kerusakan dan ganti sebelum mesin mengalami masalah. Sebelum berinvestasi dalam mesin, pastikan produsen menawarkan layanan purna jual lengkap termasuk pemasangan dan perawatan. Berinvestasi pada produk berkualitas yang terbuat dari bahan baik penting karena pada akhirnya akan lebih hemat dibanding membeli sesuatu yang lebih murah, namun tetap memiliki opsi untuk cincin oniks.

Sheenstar adalah bisnis berusia 15 tahun dengan pengalaman luas di bidang mesin pengisian dan penge labelan botol. Kami menyediakan produksi, R dan D penjualan, penjualan, dan layanan purna jual, serta terakreditasi sertifikasi ISO9001, CE, dan SGS. Kami akan mengonfigurasi mesin yang sesuai untuk pelanggan kami berdasarkan riset pasar, kuesioner, dan anggaran. Pelanggan sangat puas dengan peralatan dan layanannya. Sheenstar memiliki reputasi luar biasa di sektor mesin air dan minuman.

Opsi kustomisasi tersedia untuk memenuhi kebutuhan pelanggan kami. Kami dapat menyediakan diagram tata letak untuk pabrik bersama dengan label botol. Kami juga akan memberikan mesin pengisian dan penempelan label botol selama proses produksi mesin. Selain itu, kami memiliki departemen layanan purna jual profesional yang dapat memberikan dukungan teknis cepat dan menyeluruh. Para insinyur akan mengunjungi pabrik pelanggan untuk menginstal dan menguji operasi mesin serta melatih pekerja dalam penggunaan dan pemeliharaan mesin yang benar, memastikan operasi peralatan berjalan normal serta proses produksi pelanggan berjalan lancar.

Mulai dari pengadaan bahan baku hingga proses produksi manufaktur, perusahaan kami memiliki tim inspektur kualitas yang berpengetahuan luas dan berpengalaman. Departemen kualitas perusahaan kami secara terus-menerus memantau setiap tahapan untuk memastikan bahwa peralatan yang digunakan memenuhi standar kualitas tinggi. Peralatan tersebut terbuat dari bahan berkualitas premium SUS304/SUS316, yang mudah dibersihkan serta memiliki masa pakai yang panjang; komponen mesin pengisi botol dan pelabelan diproduksi oleh merek-merek ternama yang memiliki kualitas sangat baik serta layanan purna jual yang memuaskan.

Sistem lengkap mesin pengisian dan penempelan label Sheenstar digunakan untuk produksi minuman, termasuk air murni dan minuman buah, serta anggur, minyak, susu kedelai, dan yogurt. Kemasan dibuat dari kaca, plastik, drum, drum 5 galon, atau kaleng. Seluruh jalur produksi mencakup sistem pengolahan air, sistem pra-pengolahan minuman, mesin cetakan injeksi, mesin pembuatan botol, mesin pembersihan dan pengisian, sistem penempelan label, mesin pengemasan,以及其他 mesin.

Mesin Pengisian dan Penempelan Label Botol sangat umum digunakan dalam makanan, minuman, kosmetik, farmasi, produk rumah tangga, dll karena kemampuannya untuk menangani berbagai jenis wadah. Mesin-mesin ini memungkinkan produsen untuk menyederhanakan aktivitas produksi, membantu mereka mengirimkan volume tinggi produk dengan efisiensi maksimal dan memastikan bahwa standar kualitas tetap konsisten di setiap botol yang diisi atau diberi label.