It is very important to choose the best machines for our Sheenstar business. While this is a novel for us, we want the right tools to help us while we fill and seal and ensure that we do it quickly and easily. Some things to consider related to our bottling line equipment:

They have great importance in our business we well. It is making the bottling process faster, thus, saving us a lot of time and money and paid experience. If our machines are working properly, we can fill more bottles in less time, allowing us to make more money. We also make fewer mistakes and less waste when we have good bottling line equipment, which helps ensure that our products are high quality.

There are a few things that we need to consider when choosing bottling line equipment for our business. Next, we shall examine the machines's size and its capacity. We want machines that can fill the amount of bottles we require every day. We should decide what kind of bottles we have; all machines are designed to fit certain shapes and sizes of bottles. We also need to seek for machines that are simpler to fix and take care of, so they are capable of running smoothly for a long while.

Bottling line machines are more advanced than ever, thanks to new technology. These new machines are faster, more accurate and easier to use.” They can also connect to computer systems to monitor how many bottles we produce and identify any issues immediately. Our new bottling line equipment will help us perform more efficiently and keep us ahead of the competition.

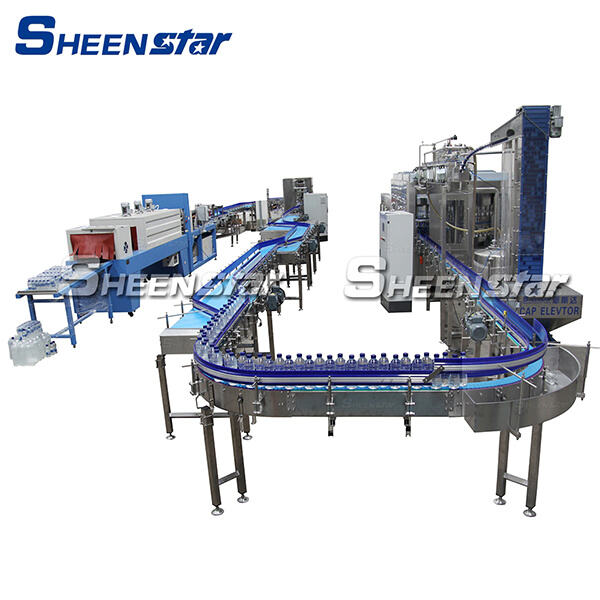

The automated bottling line machines are helpful for our Sheenstar business. These machines are able to fill, seal, and label their bottles by themselves, meaning we require less hands on deck. It saves us time and money, and increases the accuracy and consistency of our products. Automated machines can work day and night, so we can produce more bottles without hiring additional employees.

So, in order for our bottling line machines to work properly, they need to be maintained well. That means cleaning them, oiling them and checking on them regularly. If we note any problems, we will rectify them one by one so that the production line does not go down. Maintaining the machines will ensure high performance of machines in the long run to support the other unit of business (Sheenstar).