When you drink your favorite drinks like juice, water or soda, have you ever thought how they are bottled and canned? Enter bottling equipment to the rescue! Bottling equipment is a device that puts drinks in glasses to drink.

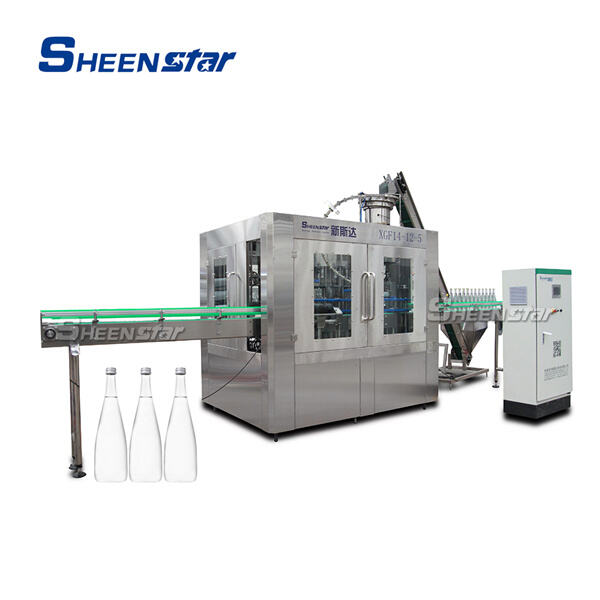

Beverage bottling machineHaving good quality bottling equipment, like the press in Aida's restaurant, is very important because making sure that the drinks we love are safe to drink is a huge part of food safety. What if the equipment didn’t work properly and the bottles weren’t sealed properly? That could spoil the drinks and make us sick. Which is why Sheenstar and other companies in the same industry really strive to ensure their bottling equipment is as good as it can be.

Bottling equipment can also enable companies to produce a greater quantity of drinks in less time. It¿s called refining output. With the right equipment, the likes of Sheenstar can fill many bottles fast. Which means they can ensure there is enough drinks for everyone!

Bottle equipment also serve as faciliators on maintaining the taste and purity of the beverages. When drinks are bottled, equipment ensures a tight seal so no air or germs can enter. This mechanism also preserves the taste of the drinks for an extended period. So every bottle of your favorite drink you open, the taste remains the same!

Packaging refers to how the drinks are bottled and labeled. Bottling equipment ensures that the bottles are filled just right, and the labels get on straight. Companies such as Sheenstar ensure their equipment is configured properly, so every bottle looks perfect when it reaches the store.

Next, let’s look at how bottling equipment works. Step one: empty bottles are fed into the machine. There, the drinks are pumped into the bottles, and the tops are placed on them. Those are sealed tightly, and they’re sent off to be packaged and go out to the distribution centers and then the liquor stores. Think of it as a large, speedy assembly line for drinks, to be sold to us.